Stamping

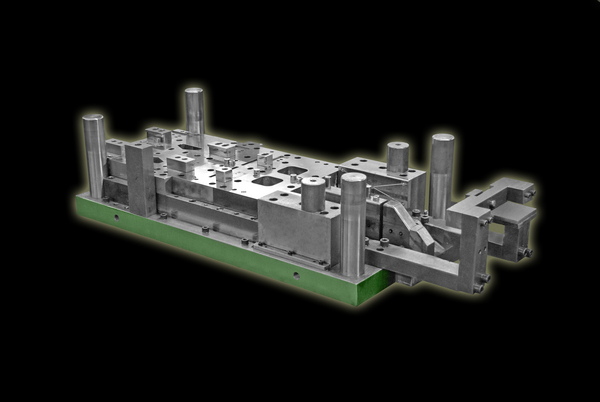

Explore the capabilities of Armor Metalstamp for all your outsourced stamping and manufacturing needs. Our comprehensive services encompass a full-service, in-house tool and die department staffed by highly skilled and experienced professionals. We custom design, engineer, build deep draw, progressive, forming, transfer tooling, and various post-stamping operations and we deliver excellence at every stage.

With facilities in Elkhart and South Bend, Indiana, serving as a centralized point for our metal stamping services, and a machining facility in Elkhart, we are strategically positioned to provide optimal support. Additional facilities in Mason, Ohio, and Lebanon, Ohio, offering assembling, engineering, fabrication, and finishing services. Armor Contract Manufacturing, through its extensive scale and unmatched capabilities, is your trusted partner for managing both large and small Midwest contract manufacturing projects.

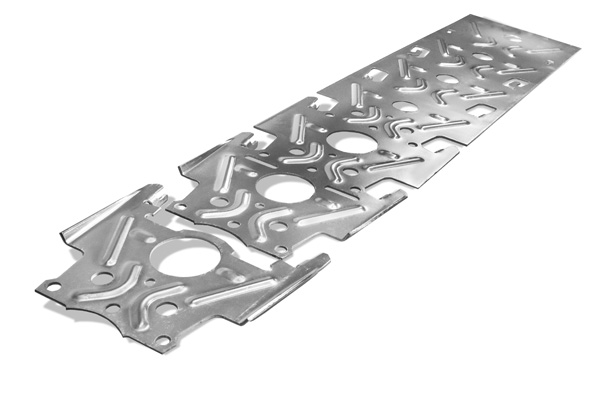

We work with carbon steel, high strength, and stainless steel, providing light to heavy gauge stamping for various industries. We are experienced in large and small production runs, large-scale units, and building to government specifications. Our streamlined contract manufacturing process allows us increased precision and control because all aspects of your project are approached uniformly and are seamlessly coordinated.

Armor Metalstamp is equipped to meet all industry standards, including automotive quality requirements for documentation and materials’ traceability throughout the process. We currently manufacture parts for various industries and can produce almost any size and shape you require.

Capabilities

We offer a full-service, in-house tool and die department with skilled, experienced professionals. To assure better control of your cost and delivery, we slit steel coils up to .5” thick, helping to provide quick turn-around on orders. Our feeders can accommodate .675” thick steel. Our 45 presses with capacity ranging between 30 and 1600-tons, and deep draw equipment. We custom design, engineer, build deep draw, progressive, forming, transfer tooling, and many post-stamping operations.

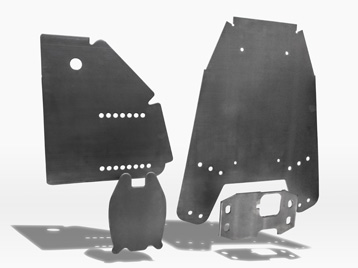

- Blank, Pierce, Compound and Progressive Stampings

- Flat Stampings of All Shapes

- Laser Cutting

- Press Brake

- Spot Welding

- Kitting and Assembly

- Vision Sorting

- Bracketry and Hinges

- Heavy Gauge Stamping

- Custom Metal Stamping

- Precision Blanking Service

- Light Gauge Stamping

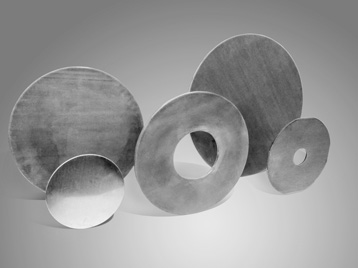

- Specialty Washers for All Industries

- Deburring, and Tumbling

- First Article/Qualification Testing Part/Tooling Types

- Blank, Pierce, and Progressive Dies

- Compound Dies

- Four Slide Applications

- Stampings of All Shapes (Blank/Pierce)

- Brackets (Variety of Shapes and Thicknesses)

- Washers, Flat, and Through-Hardened

- Belleville Washers for All Industries

- Plant Assist Production & Assembly

- Tool & Die Design Engineering, Fabrication, Repair, and Maintenance

Fasteners/Washers

With tooling for over 2,000 fasteners, we provide high-quality turnkey solutions at competitive prices. We provide personalized service for your fastener needs and complete material and processing traceability.

Industries Served

- Aerospace

- Agricultural

- Agriculture Implements and Storage

- Appliances

- Automotive

- Braking Systems

- Building/Construction

- Consumer Products

- Electrical

- Fasteners for Global Distributors

- Furniture

- Heavy Equipment and Machinery

- Lawn and Garden

- Military

- Mining

- Office Furniture

- Oil and Gas

- Recreational Vehicles

- Service Industries

- Telecommunications

- Transportation

- Truck and Trailer

Armor Contract Manufacturing can handle your outsourced manufacturing needs. Our Elkhart and South Bend, Indiana, facilities are a single point of contact for our metal stamping services. Our machining facility is also located in Elkhart. We have additional facilities in Mason, Ohio, and Lebanon, Ohio, to offer assembling, engineering, fabrication, and finishing services. Due to our scale and capabilities, we can handle your midwest contract manufacturing projects, both large and small.

For open manufacturing jobs at our Elkhart and South Bend, Indiana facilities, visit our Career page on our corporate website.