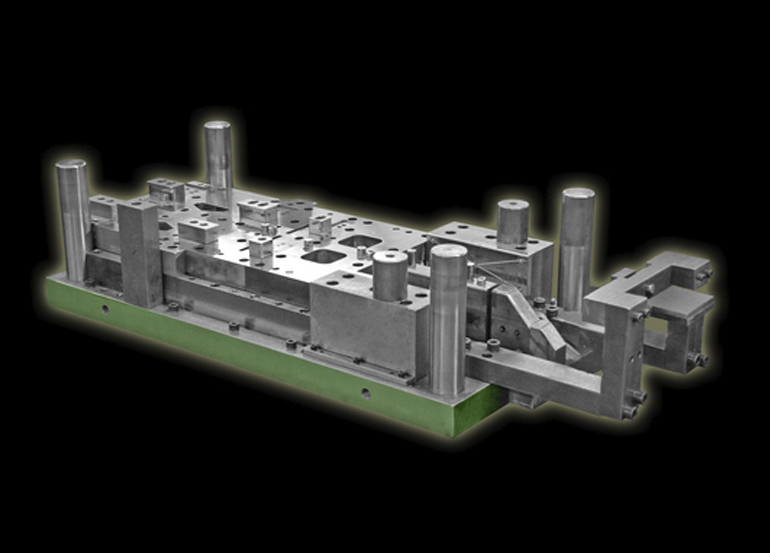

Tool & Die Design Engineering, Fabrication, Repair, and Maintenance

One-Stop Solution for Light to Heavy Gauge Stamping

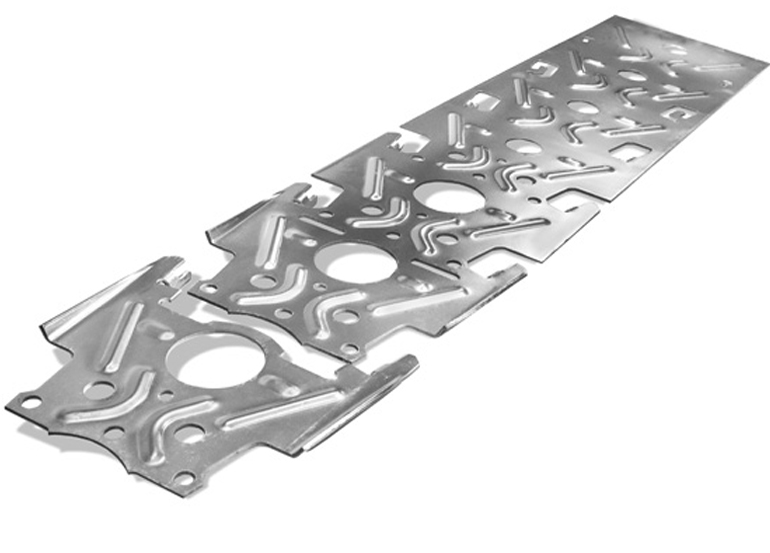

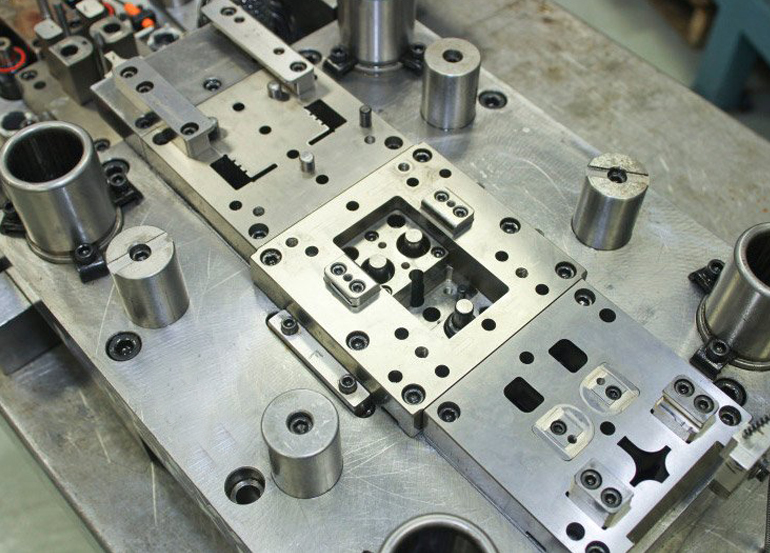

Armor Metalstamp offers custom tool and die services, including design engineering, fabrication, repair, and maintenance. We specialize in troubleshooting customers’ existing tooling. We have experience with single operation and progressive dies, as well as deep draw and custom stamping, dies. We are skilled at designing and building dies to blank, pierce, draw, extrude, form, and notch materials such as carbon, low carbon, stainless, coated, high strength, galvanealed steel, aluminum, and other specialty metals, as well as supply gages and fixtures. Armor Metalstamp works to precision tolerances for all of our tool and die projects and has a well-equipped tool room, engineering team, and supplier network to ensure a quick turnaround.

Our stamping presses range from 100 – 1500 tons and are equipped to process parts measuring up to 36” in length and up to 72” in width. Part material thickness can range from 0.020” to .625” with maintaining tolerances of 0.002”.

Armor Metalstamp has over 45 years of extensive experience designing, building, and repairing custom metal stamping dies for various industries with various applications.

Specifications

General Capabilities

Tool Design, Tool Build, and Production Engineering

Die Repair, Maintenance, and Modification Prototyping

Die Types

Stamping

Single Hit

Progressive

Transfer

Forming Dies

Draw Dies

Blanking Dies

Secondary Dies

Coining Dies

Hand Transfer Dies

Additional Capabilities

Checking Fixtures

Inspection Gages

Assembly Fixtures

Production Capabilities

High Strength

Heavy Gauge

Light Gauge

First Operation Blanks

Stamping Features

Blanking

Deep Draw

Forming

Piercing

Coining

Notching

Embossed

In Die Fastener

Countersinking

Extrusions

Press Range – 45 Presses 100 tons to 1500 tons

Part Length Up to 36″

Part Width Up to 72″

Part Material Thickness 0.020″ to .625″

Tolerance -+ 0.002″

Post-stamping Services

Assembly

Washing

Deburring

Machining

Plating

Tapping

Welding

Heat Treating

Production Volume

High Volume

Long Run

Large Scale Production

Prototype to Production

Low Volume

Small Run

Materials

Carbon Steel

High Strength Steel

Low Carbon Steel

Galvanealed Steel

Stainless Steel

Aluminum

Coated Steel

Alloys and Copper

Other Specialty Metals

Industry Standards: ISO 9001:2015

Packaging

Customer Provided Armor Metalstamp Provided

Industry Standards ISO 9001:2015

File Formats

AutoCAD (DWG,DWZ)

IGES – Initial Graphics Exchange Specification

ANSI file format

PDF