EDM

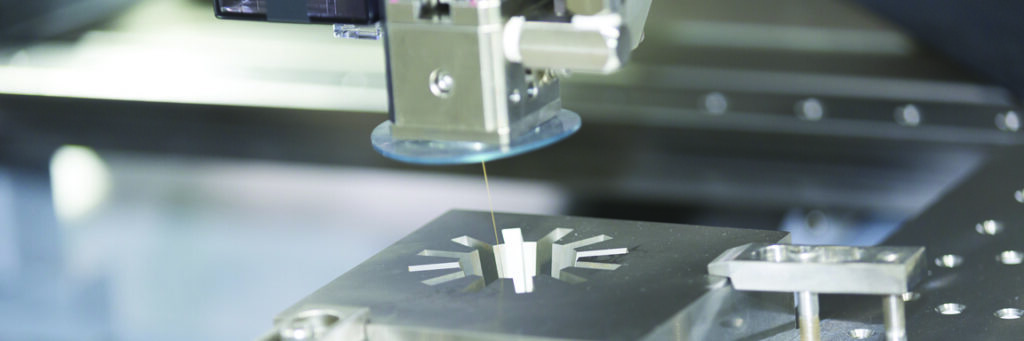

EDM (Electrical Discharge Machining) is a highly efficient and precise method of cutting and shaping materials using electrical discharges. At Armor Machining, a subdivision of Armor Contract Manufacturing, we use EDM to cut extremely hard materials, such as carbide, ceramics, and titanium, with a very high level of precision. The high level of precision that we deliver with our EDM machining allows us to serve well a variety of industries where tight tolerances are required, such as aerospace or medical device manufacturing.

Our EDM Capabilities

Complete Solution: Armor Machining offers prototyping, low-volume and full production services, as well as engineering support and assembly services.

Highly Skilled Machinists: At Armor Machining, we pride ourselves on our team of dozens of highly skilled machinists, each boasting an impressive average of 7 years of industry experience, almost double the industry average. With a proven track record of precision and accuracy, our team can tackle even the most demanding projects with ease. We are dedicated to providing the best service to our clients, and that’s why we invest in our human capital, by recruiting top talent from top trade schools and professional organizations.

Precision & Accuracy: We are dedicated to achieving the highest levels of precision and accuracy in our work. Our EDM machines allow us to machine workpieces at optimized speeds while maintaining exceptional accuracy. Our controlled deionization process maintains a constant low level of conductivity, and our use of positioning measurements with optical scales on the five axes eliminates errors. Additionally, our EDM machine’s auto geometry strategies compensate for wire drag, ensuring that our workpieces are free from defects.

Maximum Workpiece Capacity: We can handle workpieces up to 33.5” x 19.75” x 15.75”, with a maximum weight of 1100 pounds. This means that we can accommodate a wide range of sizes and materials, from small parts to large industrial components.

Tapers: We can handle a variety of taper types. We can produce conical, iso-radius, sharp corner, and mixed tapers with a maximum angle of ±30 degrees. This allows us to create precise and accurate tapers for a wide range of applications.

Complex Shapes: Our EDM machining can be used to produce complex shapes that would be difficult or impossible to produce using traditional methods. The electrode can be shaped to match the desired contour of the finished part, allowing our production of intricate shapes and internal features.

Materials: We can handle a wide range of materials including but not limited to carbide, hardened steel, tungsten, titanium.

Quality Control: Quality control is of the utmost importance at Armor Machining. We use precision measurement equipment to ensure that our parts meet the tightest tolerances. Precision is confirmed by our fully calibrated coordinate measuring machines (CMM) that provide dimensional verification up to 20”x 27” of travel.

At Armor Machining, we are committed to providing our customers with the highest level of quality and service. Our EDM and other machining capabilities, combined with our experience and expertise, allow us to deliver exceptional results on every project.

Contact us today to learn more about how we can help with your machining needs.